The Ultimate Guide to Material handling equipment: Enhancing Efficiency in Warehousing

Every step of the supply chain process must be optimized to ensure timely

delivery and customer satisfaction. Among the crucial elements of warehouse

operations is order picking, the process of selecting items from inventory to

fulfill customer orders. And when it comes to order picking, having the right

tools can make all the difference. This is where material handling equipment

come into play.

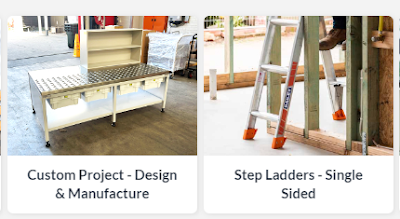

Material handling equipment, also known as picking carts or order

fulfillment carts, are indispensable assets in modern warehouses and

distribution centers. These versatile carts are designed to streamline the

order picking process, enabling workers to gather items quickly and

efficiently. From small-scale operations to large-scale distribution centers,

material handling equipmentfrom reflexequip.com.au offer numerous benefits

that contribute to overall productivity and cost-effectiveness.

What is material handling equipment?

Material handling equipment come in various shapes, sizes, and

configurations, catering to different warehouse requirements and operational

workflows. However, they typically share common features designed to facilitate

the order picking process. Here are some key components of material handling

equipment:

· Storage Space: Material

handling equipment are equipped with shelves, bins, or compartments to

accommodate a wide range of products. The layout and configuration of the

storage space may vary based on the type of items being picked and the

frequency of orders.

· Mobility: Mobility is

essential in a dynamic warehouse environment. Material handling equipment are

equipped with sturdy wheels that allow them to move smoothly across different

surfaces, including concrete floors and warehouse aisles.

· Maneuverability:

Efficient maneuverability is crucial for navigating through narrow aisles and

tight spaces within the warehouse. Many material handling equipment feature swivel

casters or ergonomic handles for easy steering and control.

· Durability: Given the

rigorous demands of warehouse operations, material handling equipment are built

to withstand heavy loads and frequent use. They are typically constructed from

robust materials such as steel or aluminum, ensuring long-term durability and

reliability.

Types of Material handling equipment

Material handling equipment come in several types, each tailored to

specific warehouse requirements and operational workflows. Some common types

include:

Multi-Level Trolleys: These trolleys feature multiple shelves or levels,

allowing for efficient organization and storage of various items. Multi-level

trolleys are ideal for warehouses with a diverse product range and high order

volumes.

Pallet Trolleys: Pallet trolleys are designed to transport palletized

goods within the warehouse. They feature a flat platform or base that can

accommodate standard pallet sizes, making them ideal for bulk picking and

transportation.

Bin Trolleys: Bin trolleys are equipped with bins or compartments for

sorting and storing smaller items. They are commonly used in warehouses with a

high volume of small parts or components.

Order Picking Carts: These versatile carts are specifically designed for

the order picking process, with features such as adjustable shelves, tilt bins,

and ergonomic handles. Order picking carts are highly customizable to

accommodate different picking methods and inventory requirements.

Benefits of Using Material handling equipment

The adoption of material handling equipment offers several benefits for

warehouses and distribution centers:

Increased Efficiency: By providing workers with a designated space to

organize and transport items, material handling equipment streamline the

picking process, reducing the time and effort required to fulfill orders.

Improved Accuracy: With proper organization and labeling, material

handling equipment help minimize picking errors and ensure accurate order

fulfillment, enhancing customer satisfaction and reducing returns.

Enhanced Ergonomics: Ergonomic design features such as adjustable shelves

and comfortable handles reduce strain and fatigue for warehouse workers,

promoting a safer and more productive working environment.

Optimized Space Utilization: Material handling equipment maximize the use of available warehouse space by

efficiently organizing and storing inventory, minimizing clutter and congestion

in aisles and storage areas.

Flexibility and Versatility: With a wide range of configurations and customization

options, material handling equipment can be tailored to meet specific warehouse

requirements and adapt to changing operational needs.

Comments

Post a Comment