Enhancing Sustainability in Material Handling Equipment

In an era marked by a growing emphasis on environmental consciousness, the world of material handling is undergoing a transformation towards a more sustainable future. As industries recognize the urgent need to reduce their ecological footprint, the integration of eco-friendly practices into material handling operations has taken center stage. Let's delve into the strategies and innovations that are enhancing sustainability in material handling equipment experts from reflexequip.com.au and reshaping the way goods are moved and managed.

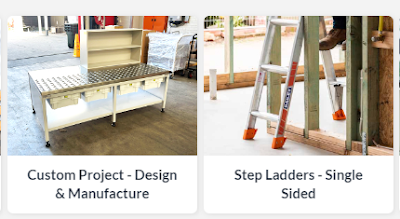

Eco-Friendly Material Handling

Equipment: A New Horizon

One of the fundamental shifts towards sustainability in material handling lies in the design and manufacturing of eco-friendly equipment. Companies are now focusing on developing machinery with reduced energy consumption, lower emissions, and recyclable components. Electric forklifts, for instance, are gaining popularity due to their zero emissions and quieter operation, making them ideal for indoor use without compromising air quality.

Energy Efficiency: A Crucial Component

Material handling equipment can be energy-intensive, but advancements in energy-efficient technologies are changing the game. Regenerative braking systems in forklifts capture and convert kinetic energy back into usable power, reducing overall energy consumption. Additionally, solar panels integrated into equipment design can harness renewable energy, further minimizing the reliance on traditional power sources.

Green Packaging and Efficient Space Utilization

Sustainability in material handling extends beyond equipment design—it encompasses packaging and space utilization as well. Companies are embracing eco-friendly packaging materials that reduce waste and promote recyclability. Moreover, optimizing storage and warehouse layout through advanced shelving systems minimizes space wastage and improves overall operational efficiency.

Sustainable Practices and Workforce Training

Sustainability in material handling goes beyond technology—it's about cultivating a mindset. Workforce training programs are focusing on eco-conscious practices, emphasizing energy-efficient equipment operation and waste reduction. Employees are becoming key players in the sustainability journey, driving positive change within their organizations.

Collaborative Supply Chain Initiatives

Embracing sustainability often requires collaboration across the supply chain. Manufacturers, suppliers, and distributors are joining forces to adopt greener practices collectively. From sourcing materials responsibly to implementing shared transportation solutions, these collaborations amplify the positive impact on the environment.

Reimagining Reverse Logistics

The sustainability equation is incomplete without addressing the challenges of reverse logistics—the process of handling returned products. Companies are devising innovative ways to refurbish, recycle, or repurpose returned items, reducing waste and contributing to a circular economy.

Conclusion:

As the world rallies behind the call for sustainability, the material handling industry is at the forefront of change. The evolution of eco-friendly material handling equipment, coupled with energy-efficient technologies and intelligent systems, is reshaping the way goods are managed, transported, and stored. Embracing sustainability isn't just a choice; it's a responsibility that holds the promise of a greener tomorrow for generations to come. By harnessing the power of innovation and collaboration, the material handling sector is forging a path toward a more sustainable and prosperous future.

Comments

Post a Comment